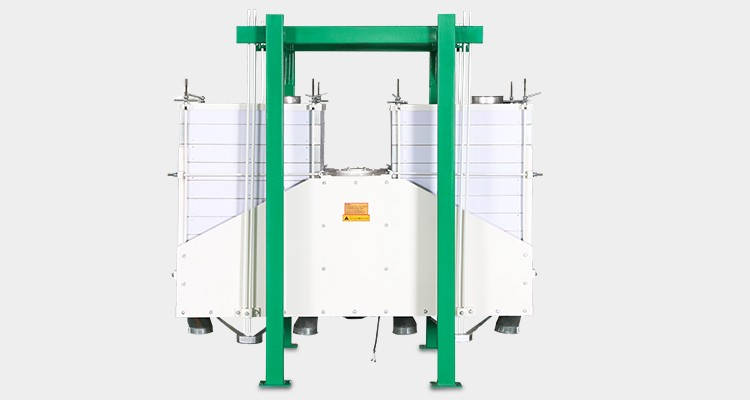

Flour Sifter Twin-Section Plansifter

Umatshini wokuhluza

Iplanifter yecandelo lamawele luhlobo lwezixhobo zokugaya umgubo.Isetyenziselwa ikakhulu ukuhluzwa kokugqibela phakathi kokuhluzwa ngeplanifter kunye nokupakishwa komgubo kwiindawo zokusila zomgubo, kunye nokuhlelwa kwezinto ezixubileyo, umgubo wengqolowa orhaxaxa, kunye nezixhobo eziphakathi, ezigayiweyo.Okwangoku, yamkelwe ngokubanzi kwiindawo zokusila zomgubo zanamhlanje kunye nerayisi yokusila.Sinokubonelela ngoyilo lwe-sieving eyahlukeneyo yokusebenza okuhlukeneyo kunye nezixhobo ezahlukeneyo eziphakathi.

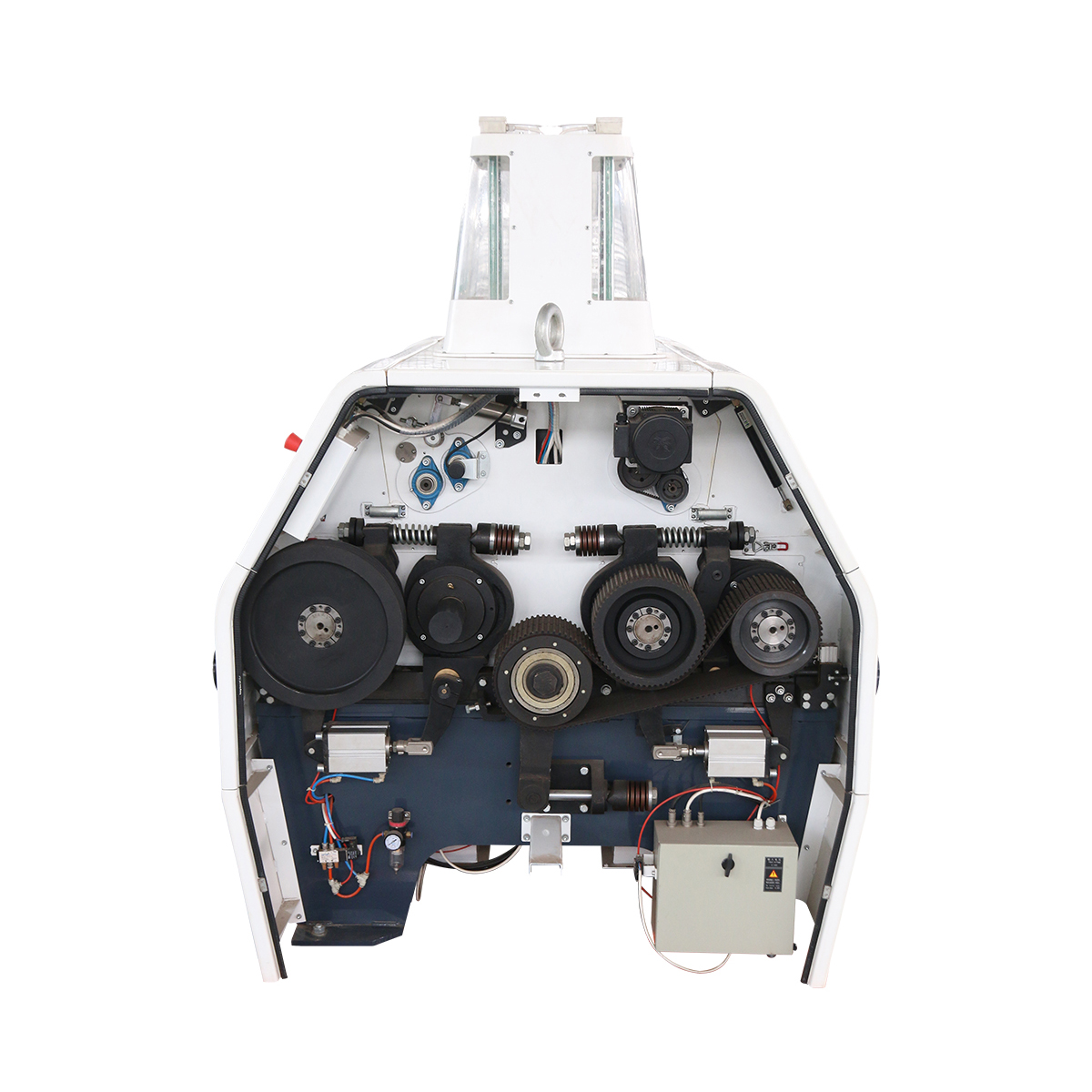

Umgaqo wokusebenza

I-Sifter iqhutywa yi-motor efakwe phantsi kwesakhelo esiphambili ukwenza i-plane rotary motion ngokusebenzisa ibhloko eccentric.Izinto eziphathekayo zondliwa kwi-inlet kwaye zihamba phantsi inyathelo ngesinyathelo ngokoyilo oluhlukeneyo lwezixhobo ezahlukeneyo, kwaye ngexesha elifanayo lihlulwe kwimijelo emininzi ngokobukhulu bamasuntswana.Izinto eziphathekayo zinokwahlulwa zibe max.ezine iintlobo zezinto.I-flow sheet inokuthi yenziwe ngeemfuno ezahlukeneyo.

Uphawu

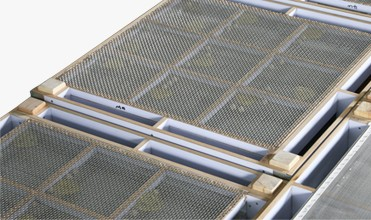

1. Ubungakanani besakhelo se-sieve yeplanifter ifumaneka kwi-630×630mm, 700mm×700mm, 830mm×830mm, 100mm×100mm.

2. Uyilo lwemodyuli luyaziswa, ngoko unokutshintsha ubungakanani besakhelo se-sieve ukuze ufumane ukusebenza kwe-sieving eyahlukeneyo ngokweemfuno.

3. I-counterweight ehlengahlengiswayo ifakwe kunye neebheringi ze-SKF (Sweden).

4. Iifreyimu ze-sieve ze-twin-section planifter zenziwe ngamaplanga angaphandle, kwaye zigqunywe ngeplastiki ye-melamine lamination.Ziyakwazi ukuchithwa kwaye zitshintshe, kwaye zixhotyiswe ngeetreyi zensimbi ezingenasici.Icandelo ngalinye linyanzeliswa ngesakhelo sesinyithi kunye noxinzelelo lwe-screws micrometric ukusuka phezulu.Kulula kwaye kuyakhawuleza ukutshintsha iskimu sokuhluza seplanifter ukuba kuyimfuneko.

5. Iplanifter yethu yamacandelo amabini iza namacandelo amabini, ngoko ke umthamo wayo wokuvelisa uphezulu kunolo lwe-mono-section planifter.Inobukhulu obuncinci, ubunzima obulula, kwaye ihlala kwindawo encinci kuphela.

6. Ipakethi ye-sieves inqunyanyiswa ngesakhelo sayo esifakwe phantsi okanye sixhonywe ngesakhelo esahlukileyo esimiswe kwisilingi.

7. Izisefu ze-SEFAR azinyanzelekanga.

Uluhlu lweeParameters zobuGcisa

| Uhlobo | Isakhelo seSifter | Indawo yokuhluza | Isantya seShaft esiPhambili | Umthamo | Rotary | Amandla | Ubunzima | Ubume boBume |

| (iqhekeza) | (㎡) | (r/min) | (t/h) | Ububanzi | (kW) | (ikg) | LxWxH(mm) | |

| FSFJ2x10x63 | 6-12 | 4.2 | 290 | 2-2.5 | Ø45-55 | 1.1 | 550-580 | 1680x1270x1500 |

| FSFJ2x10x70 | 8-12 | 6.2 | 265 | 3-3.5 | Ø45-55 | 1.1 | 650-670 | 1840x1350x1760 |

| FSFJ2x10x83 | 8-12 | 8.5 | 255 | 5-7 | Ø45-55 | 1.5 | 730-815 | 2120x1440x2120 |

| FSFJ2x10x100 | 10-12 | 13.5 | 255 | 8-10 | Ø45-55 | 2.2 | 1200-1500 | 2530x1717x2270 |

Iinkcukacha zeMveliso

Uyilo lwekhompatimenti evulekileyo nevaliweyo zombini ziyafumaneka.Indawo ye-sieve yohlobo oluvaliweyo inkulu kwaye ukutywinwa kungcono.

Isakhelo se-sieve yeplanga, iplastiki egqunywe ukuphepha ukuguquka okufumileyo, i-6-12 ilungiselelo lesakhelo se-sieve ngokwemfuno ezahlukeneyo.

Ukucinezela okudityanisiweyo okuthe nkqo nokuthe tye ukuqinisekisa ukuba isakhelo sesisefu siqinile, akukho kufuduswa, akuvuzi.

Ukumiswa kwentonga ye-Fiberglass ukwenzela ukubaleka okuzinzileyo kunye nokuqalisa okufutshane kunye nexesha elifutshane.

Ulungiselelo lwesakhelo sesefo esilungiselelwe ngokwemfuno ezahlukeneyo

Ngathi